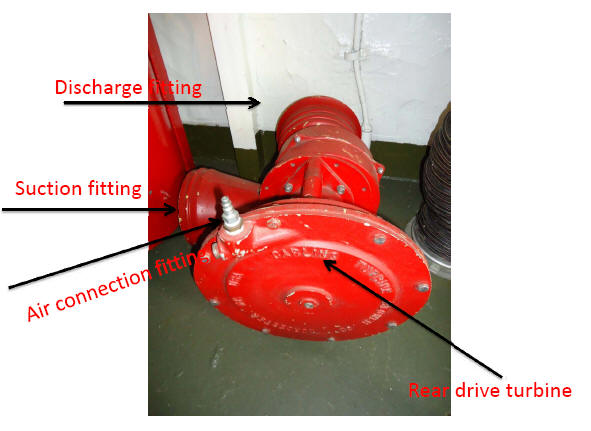

| The air turbine driven blower, developed in 1951, was safe

for use in any gaseous atmosphere. It was a pneumatic blower

developed to exhaust air containing explosive vapors. It was

used in fire and post-fire desmoking operations, and during

interior painting operations to remove the toxic fumes. The

blower was also used extensively for gas-free evolutions in

tanks such as those for Navy standard fuel oil (NSFO), diesel

fuel marine (DFM), gasoline, diesel, JP-4 and JP-5 jet fuels,

after Butterworth tank cleaning operations, and occasionally in

voids and ballast tanks. This blower had a capacity of 750 cfm

with about 100 feet of 8-inch hose attached. The compressed air

supplied to the turbine did not exceed 80 psi.

The blower was operated by setting up and connecting the

5/8-inch by 25- or 50-foot rubber air hose to the ship’s low

pressure air system connection using a quick connect/disconnect

fitting. The LP air system held a pressure of 150 psi, except

for tenders and repair ships, which held a pressure of 125 psi.

The blower required at least 125 psi air to operate efficiently.

By positioning the unit directly over a scuttle, manhole, tank

cover or manhole opening, it could remove or supply 750 cfm of

air and provide ventilation. This could also be accomplished by

inserting the 8-inch by 15-foot portable, collapsible vent

ducting in the space. Up to four sections of ducting could be

attached to the blower.

The unit weighed 62 pounds and was painted red. It could be

transported by one person, while two additional personnel

transported the air ducting trunks and air hose. At least two

personnel were required to set up the unit and monitor its

operation. Damage control personnel maintained the air turbine

driven blower.

One air turbine driven blower was on the DC and hull

allowance lists for a repair locker, with one manufacturer

maintenance, parts and repair manual, four lengths of ducting,

one 8-elbow (for angled or off set attachments of air ducting)

and two 25-foot lengths of 5/8-inch rubber air hose. |