| The DC shoring chest was a large sheet metal chest

containing the tools necessary to complete emergency

shoring repairs. The chest measured 18 by 24 by 36

inches and was fabricated from 16-gauge sheet metal. It

weighed about 80 pounds, depending on the presence of

sand, wedges and nails that were used in training

scenarios until replaced. The chest had three

compartments. The first contained various wedges of

specified sizes to match common shoring widths. The

second included one 1-inch cold chisel, one firmer

chisel, one caulking iron, two 20-ounce claw hammers,

one half hatchet, one lathing hatchet, eight adjustable

clamps (four each 6- and 8-inch), one 5-pound box of

16D, one 10-pound box of 20D, and one 10-pound box 30D

common steel nails, one 6-foot carpenter’s folding rule,

a 50-foot steel tape, 5 pounds oakum, one 1-pound ball

of marlin, two 5-pound spike mauls, one 10-pound sledge

hammer, one 75-foot sounding tape, one carpenter’s

square, and two 26-inch crosscut saws. The third

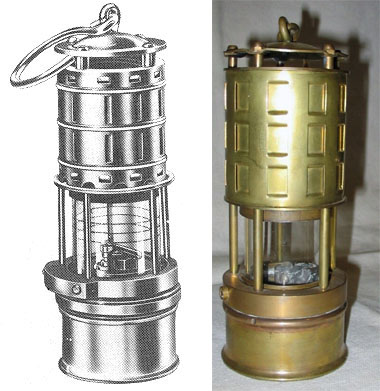

compartment contained ten 2 by 4 by 12-inch blocks of

wood, two flashlights (or one electric hand lantern) and

one 5-pound bag of sand. The main locker could provide

items not included in the damage control shoring chest.

One such item was a 50-foot, explosion-proof safety

light for emergency lighting, which was often rigged due

to loss of electrical power in the space. For measuring

and cutting wooden shores, two shoring battens (for

shores up to 7 and 12 feet) and an electric, 10-inch

circular saw and a 50-foot extension cable were

available. Wooden shores (4 by 4 inches by 12 feet, 6 by

6 inches by 12 feet, and 2 by 12 inches by 10 feet

planks) were generally stored in passageways above the

water line on the damage control deck. Six personnel

were required to transport shoring materials to the

scene or staging area. Two personnel were needed to

transport the DC shoring chest. Each timber weighed from

43 to 63 pounds, requiring four personnel to transport

them. |