| Plugging materials were provided in each damage control

repair locker. A metal tool box contained 1-inch cold chisels,

caulking irons, a ball peen hammer, a hatchet and a flashlight.

A canvas bag containing oakum, marlin, a 5-pound spike maul, a

26-inch crosscut saw, and numerous plugs and wedges of varying

sizes was carried to the damage scene. Some tools were taken

from the main locker as needed. A 21- or 36-inch Stillson

wrench, or a crow’s foot, was used to secure valves that were

seized, sprung or otherwise impossible to close or open without

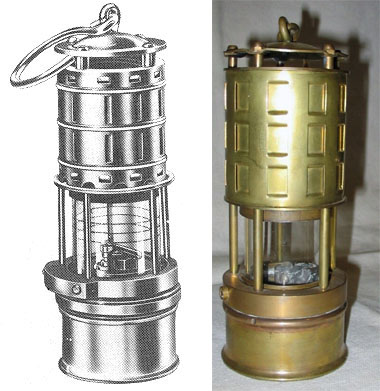

a leverage tool. Portable flood lanterns, or emergency lighting

that could be rigged, was provided when there was a loss of

electrical power in the space. A ½-inch electric drill, with a

50-foot extension cable added in 1958, a pneumatic drill with up

to 100 feet of air hose or a hand drill were also available in

the repair locker if required. |