| In cases of damage where there were jagged protrusions,

Sailors had to install either patches from the exterior side or

box patches on the interior. There were three methods used for

these repairs: the pillow patch, mattress patch and box patch.

Pillow and mattress patches were installed from the exterior.

While interior patches required less to no rigging, they were

quicker, less complicated, safer and usually secured with

wooden, steel angle or pipe shoring. For some holes protruding

outward, Sailors installed a prefabricated patch on the inside,

securing it with T, J, L or folding “T” bolts, a line with turn

buckles, or shoring. Using these methods and procedures, they

patched areas where rates of flooding were the highest first.

During damage repairs, reports were made to the on scene

leader when the hole was under repair, the flooding rate, when

the repairs were completed, when the compartment was being

dewatered, upon completion of dewatering and residual leakage,

if any.

- Pillow Patch

This method of temporary DC repair was quick, simple and

required few personnel. Prefabricated materials could be

used, or personnel could improvise a suitable patch.

For holes protruding inward, an excellent patch could be

quickly made with a pillow with a hole punched in the

center. The back-up board and plate also had to have a hole

in the center. A stout line was passed through the padding

and board and knotted on each side of the patch assembly

securely. The entire patch was then placed on the outside of

the hole and hauled into position. The weighted, bitter end

of the line was passed through the hull hole. A Sailor

retrieved the line and attached it around a stanchion. A

Spanish windless was fabricated to take in the slack and

create tension on the patch line until it was securely

pulled into place. Once secured, they tied it off and

secured the Spanish windless to prevent it from unwinding.

For holes protruding outward, the patch was installed on the

inside and secured with either a T, J L or folding “T” bolts

and a line with turn buckles; otherwise it could be shored

it in place.

A boatswain’s mate second class (BM2) was in charge, with

three personnel required to fabricate, rig and install the

patch. They were usually one boatswain’s mate and two damage

controlmen (DCs) or carpenter’s mates from repairs 1 and 3

and their unit lockers.

- Mattress Patch

Mattress patches were used on damage generally caused from

shell, bomb or torpedo fragments. This method of temporary

DC repair took more time, was more difficult to fabricate

and rig, was more risky and required more personnel.

To fabricate the mattress patch, Sailors started by drilling

two holes through a mess table top and mattress. They ran

two ¾- by 10-inch long threaded eye hook bolts through the

holes in the table top, then inserted large washers and

backing plates. Oakum was wrapped around the throat of the

bolt stock on each side, between the nuts and washers, to

reduce leakage. The bolts were then tightened to a snug fit.

They also drilled 5/8-inch holes in each end of the table or

backing plate to insert and tie off ½-inch guy lines. A

1-inch by 25-foot line was inserted through the eye hooks.

For weight to facilitate catching the line and hauling it in

through the damage hole, Sailors attached a large set of

steel washers or metal “O” rings on the bitter end of the

line.

As the mattress patch was lowered over the side, guy lines

were used fore and aft to control the movement and guide the

patch into place. A Sailor stood by in the designated

damaged compartment below decks to retrieve the line and

patch, pull the bitter end of the line through the damage

hole opening and attach it around a stanchion or other

stable structure. A Spanish windless was fabricated to take

in the slack and create tension on the patch line until it

was securely pulled into place. Once secured, they tied it

off and secured the Spanish windless to prevent it from

unwinding.

A boatswain’s mate first class (BM1) was in charge because

of the rigging and safety involved, with four to five

personnel required to fabricate, rig and install the patch.

The team usually came from repairs 1 and 3 and their unit

lockers and included one boatswain’s mate for rigging, two

damage controlmen (DCs) or carpenter’s mates to fabricate

and assist in rigging, and one shipfitter-metalsmith (SFM)

for welding if required and fabrication.

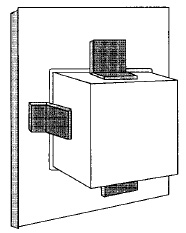

- Box Patch

This method of temporary DC repair was quick, simple and

required fewer personnel than pillow or mattress patch

methods. Prefabricated materials could be used, or personnel

could improvise a modified patch to match the damaged hull

configuration.

Patching for holes protruding inward, and especially for

holes with jagged edges sticking inboard, were miniature

cofferdams or open box patches. It could be made of either

wood or metal. The open wooden box was usually 18 inches

square and 6 inches deep. It could be made and shaped to fit

the contour of the hull, fitted with a rubber gasket, placed

over the hole, and shored in place. The steel boxes were

fabricated with the same dimensions, with a rubber gasket

glued around the 1-inch face of the box patch and welded

with angle iron. “L”-shaped clips, 4 by 1 ½ by 1 ½ inches,

were welded on top for shoring anchor points. Some box patch

sizes were prefabricated and stored near the repair lockers

in each section of the ship.

A damage controlman (DC) or carpenter’s mate was in charge

and assisted, with one shipfitter-metalsmith (SFM) for

welding, fabrication and installing the patch. These

personnel were usually from repairs 2, 3 or 5.

|