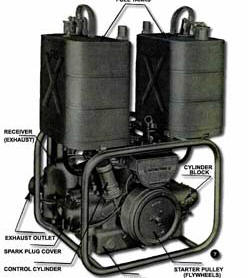

| The P-500, a portable, centrifugal-type water pump, was

driven by a compact two-cycle, four-cylinder, water-cooled

gasoline engine of special design. It was intended primarily to

be used for supplying water for fighting fires, but it could

also be used for shipboard emergencies such as removing water

from flooded compartments and bilges. Developed in 1943, it

began to be phased out and replaced by the P-250 pump in 1965,

although several remained in service through the early 1970s.

The P-500 weighed about 233 pounds without the suction hose,

strainer and two gasoline tanks. Each fuel tank contained 7 ½

gallons of an 80- to 100-octane gasoline and oil mixture.

Filled, they weighed 52 ½ pounds each. With a fuel consumption

rate of 6.9 gallons per hour, each tank ran the pump for one

hour. Most ships carried spare 55-gallon drums of gasoline for

the pumps on the fantail; each 55-gallon drum operated the pump

for almost eight hours.

The speed of the engine and the water delivery pressure were

controlled by a special pressure regulator, which could be set

between 75 to 140 psi; it was usually set for 100 psi. At this

pressure and using a 4-inch suction hose, the pump delivered 500

gallons of water per minute with a suction lift of 16 feet. With

an eductor, the lift could be increased to 50 feet or more, but

the water delivery dropped proportionately. The pump could

supply six 1 ½-inch hoses with a pressure of 100 psi. It could

maintain this pressure using standard all purpose nozzles (APNs),

with or without 4- or 10-foot applicators. However, the pump

could maintain a pressure of only 75 psi with an eductor in use.

This was the performance capability when supplying one 2 ½-inch

hose with the APN or three 1 ½-inch hoses with APNs attached,

with or without applicators.

For firefighting class Bravo fires topside or below decks,

one or two 1 ½-inch hose lines supplied foam using a mechanical

foam nozzle (MFN) with the Navy pick-up unit (NPU).

At least eighteen personnel were required to transport the

pump and accessories and to rig the pump for deep suction

operation. In ship wide or major emergencies, any member of the

ship’s company could provide assistance with this and operating

the pump. Otherwise, pump teams from repair party lockers

operated the pump. The repair lockers with specific P-500 pump

teams were 1, 1B, 2 and sometimes 3, depending on the ship’s

class.

Suitable means had to be provided to carry the poisonous

exhaust gases into the clear, particularly when the pump was

used below decks. A standard 2½-inch rubber suction hose was

coupled to the exhaust outlet to remove the gases.

Before the pump was placed in operation, it had to be primed

with water. One method of priming was to use a hand-operated

vacuum pump, to draw air from the pump body, and a 4-inch, hard

rubber suction hose, causing these spaces to be filled with

water. This method would not work on suction lifts over 16 feet.

For higher lifts, bucket priming was used. In this method, the

pump body and suction hose were filled through a cap opening on

the top of the pump housing. To use this second method, a tight

foot-valve on the lower end of the suction hose was used to

prevent escape of the priming water and to retain prime.

After being operated with sea water, the pump had to be

drained and flushed with fresh water before being restored. The

pumps were generally stowed topside in water- and fume-proof

sealed covers for safety because of the gasoline tanks, as well

as to reduce salt water corrosion. |