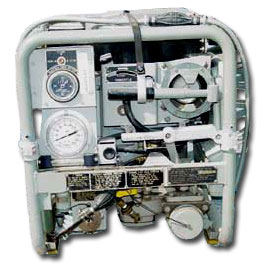

| Designed for firefighting and dewatering operations,

the P-250 Mod 1 pump was developed in 1985 to replace

the gasoline-driven P-250 and PE-250 pumps. It was a

250-gpm, portable, two-cycle, two-cylinder,

gasoline-driven pump, rated at 40 horsepower. Ignition

was by magneto built into the flywheel and controlled by

an electronic power pack. Lubricating oil, NMMA TCW-II,

was provided in a tank with a sight glass. A variable

ratio oiler (VRO) pump was installed to pump oil to and

lubricate the engine components. Engine cooling was

achieved by redirecting a small quantity of pump

discharge water. The fuel was 80- to 100-octane

gasoline. The six-gallon fuel tank provided one hour of

operation. The pump consisted of an engine, centrifugal

pump, primer pump, water outlet gate, pressure

regulator, self-winding pull starter, electronic power

pack, fuel tank, oil tank, VRO, motor controls and a

pressure regulator with gauge. Accessories provided with

the pump included a special tri-gate valve having two 1

½-inch and one 2 ½-inch male connections, a 3-inch by

10-foot hard rubber suction hose, a 2 ½-inch by 20-foot

exhaust hose and a foot valve strainer. The pump weighed

157 pounds without the fuel tank. The pump was

self-priming up to 16 feet; manual priming was required

for greater suction lifts. The 2 ½-inch discharge hose

could be connected to an eductor for lifts above 20

feet. A 3-inch male suction connection and the discharge

side had a 2 ½-inch male connection to attach a hose,

wye-gate or tri-gate for multiple hose runs in

firefighting. The pump could supply three 1 ½-inch fire

hoses or one 2 ½-inch hose for topside firefighting, or

it could provide the actuation water for an eductor in

below decks operations. The pump required two personnel

to transport it. Eleven personnel were required to set

up and rig it for operation. In ship wide or major

emergencies, any member of the ship’s company could

provide assistance in operating the pump; otherwise,

pump teams from repair party lockers rigged and operated

the pump. The repair lockers that had specific P-250 Mod

1 teams in Condition I were 1, 2, and sometimes 3 and 4,

depending on the ship’s class. Suitable means had to be

provided to carry the poisonous exhaust gases into the

clear, particularly when the pump was used below decks.

A 2-inch by 20-foot rubber exhaust hose was coupled to

the exhaust outlet to remove the gases through an

alternate overboard discharge connection when operating

on the DC deck. After being operated with sea water, the

pump had to be flushed with fresh water and drained

before being restored. The pumps were generally stowed

topside in water- and fume-proof sealed covers for

safety because of the gasoline tanks, as well as to

reduce salt water corrosion. The P-250 Mod 1 pump was

replaced by the P-250 Mod 2 pump in late 1989. |