| The electric submersible pump (sub pump), with the

old style bronze body, was in service from the 1940s

through 1970s. It was extremely useful, although heavy

at 156 pounds, in dewatering. All U.S. Navy surface

ships were required to have them; one to six were

provided in repair lockers on the hull and DC allowance,

depending on the size of the zone or area of

responsibility and the ship’s class. The submersible

pump was a water-cooled pump powered by 440 volts. It

was equipped with a 2 ½-inch male suction connection, a

2 ½-inch male discharge connection with handle, a

50-foot line for lowering the pump, and a 50-foot

electrical cable with switch. The electrical cable was

joined to the lowering line. A foot valve acted as a

check valve and allowed the pump to be primed. The

suction hose was a 2 ½-inch, 10-foot long hard rubber

hose. The rate or gpm of the sub pump varied according

to the static head (i.e., the vertical distance the

water had to be pumped). The larger the static head, the

less it would pump. The rate of the sub pump was 180 gpm

at 50 feet of static head or 140 gpm at 70 feet of

static head. The sub pump was designed to pump a variety

of liquids. The sub pump could pump water, diesel fuel,

JP-5 and light oil. It was not designed to pump some

fluids, such as gasoline, heavy oil and hot water

because of explosion hazards or because the fluid would

not cool the pump properly. The star strainer was a

cylindrical, perforated, corrugated metal strainer. The

corrugated folds looked like a star from the top, giving

the strainer its name. The sub pump fit snugly inside

the star strainer, and the strainer was then screwed

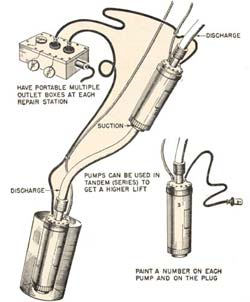

onto the suction side of the pump. To overcome large

discharge static heads on larger ships, two or more sub

pumps were connected together in series or in tandem.

Because the higher of the two pumps was not submerged,

the lowest pump had to always be energized first. Once

water filled the second pump, it could be energized

also. To the left is a diagram of two sub pumps running

in tandem. A 2 ½-inch double female adapter was needed

to connect the discharge from pump #1 to the suction of

pump #2. The submerged pump was inserted in a basket

strainer. A special connector allowed three pumps to be

connected to a single 440-volt outlet. Below is a table

of manufacturers’ submersible pump limitations. |