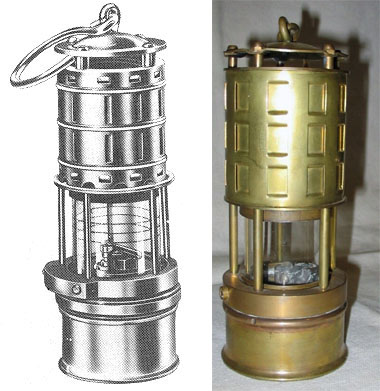

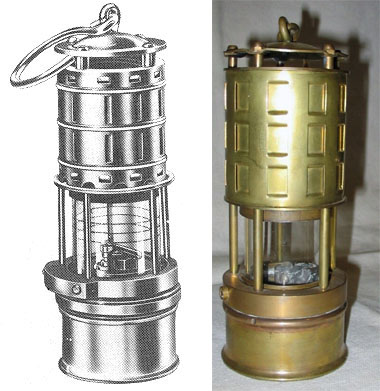

| The flame safety lamp was used for many years, from

before WWII until the 1970s. While it could detect the

presence of flammable gases, it was intended solely to

test an atmosphere for oxygen deficiency, to ensure that

sufficient oxygen was present to support life. The lamp

was constructed of non-sparking brass and had a glass

globe and cotton wick. The lamp used naphtha as its

fuel. Explosions did occur because of defective parts,

incorrect procedure, or improper assembly of the lamp.

When testing with the flame safety lamp, it had to be

moved carefully and slowly while holding it as close to

vertical as possible. The following indications of flame

behavior were a result of conditions in the atmosphere

being tested; these indications had to be assessed by

the test observer: Flame dies out: insufficient oxygen

(less than 16% by volume) Flame dies out with a slight

“pop”: explosive concentration of gases or vapors Flame

flares up brightly: less explosive concentration of

gases or vapors Flame flares up, then goes out: rich

concentration of explosive gases or vapors The test

observer had to ensure that the flame safety lamp flame

burned for five minutes, with the flame adjusted to 3/8

inch, for proper warm up before it was allowed to be

taken into a space. It had to remain under constant

observation while testing, and it had to be kept still

for several seconds in each location. When entering a

tank, void or compartment with the flame safety lamp,

the test observer had to wear an OBA or hose air-line

mask. |