|

|

|

|

| HOME |

| ABOUT US |

| PARTICIPATE |

| COLLECTIONS |

| DC EQUIPMENT MUSEUM |

| SHIP&SUBMARINE MUSEUM |

| WW II DAMAMGE REPORTS |

| SHIPBOARD CASUALTIES |

| DAMAGE CONTROL MUSEUM |

| DC EQUIPMENT Museum |

| Firefighting Systems |

| High Capacity Fog Foam System |

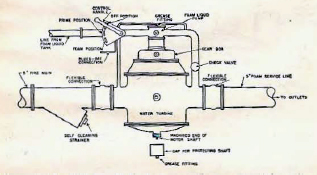

High Capacity Fog Foam System .Aircraft carriers were equipped with another type of mechanical foam generating equipment known as the high capacity fog-foam system. This system consists of foam proportioners which inject foam liquid into auxiliary fire main risers. On carriers of the CVB-41class there were 15 proportioners; of those of the CV-9 class, 10 proportioners; on ships of the CVL-48 class, 8 proportioners ; on the CVE-105 class, 5 proportioners. All of these proportioners have a capacity of 1000 gpm. Risers from the foam-injection stations terminate in a 3 inch monitor and a 2 inch hose outlet on the hangar deck, an l and 1/2 inch hose outlet on the fl ight deck. The foamoutlet stations immediately fore and aft of the hangar consist of 3 and 1/2 inch and 2 and 1/2 inch hose outlets. On CV and CVD class carriers, a 2 1/2 inch outlet is also provided adjacent to the access to the elevator pit. The Bureau of ships developed and tested two types of high capacity fog-foam systems for installation on air craft carriers. The major difference between the two is that in one the risers from the foam-injection system was charged and one was dry.  The proportioner consists of a positivc displacement water motor coupled to a positive displacement foam liquid pump. The firemain drives the water motor, which in turn drives the foam liquid pump, injecting the foam liquid into the foam line riser. The pump and water motor are of such design that the combined discharge consists of 3 to 6% foam and 97 to 93% sea water. For more information, see the Index. |