|

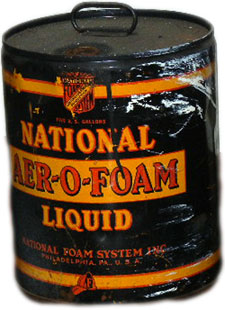

Type V mechanical foam liquid was a solution foaming agent.

Foam was prepared by mixing the foam forming liquid with a water

stream passing through a hose or pipe, forming a 6% solution.

The foam production occurred at the terminal nozzle, which was

designed so that air was introduced, causing the foam-water

mixture to expand by forming large quantities of foam.

The

quantity of mechanical foam liquid provided was determined in

the design phase of the ship. At this time, BU-Ships conducted

fire load studies. The results, in addition to the appropriate

proportioner operating capacity requirements of the unit or

system, were considered in determining the quantity provided.

Portable, 5-gallon cans of foam were stored where class “B”

fires could potentially develop; these were stowed on racks, two

to ten cans per rack. Installed equipment/system tanks could

hold 10, 50, 500 or 1,000 gallons of mechanical foam. Ships were

loaded out with 120 to 600 spare cans of mechanical foam; larger

ships had twenty or more additional 55-gallon drums. The spares

were used to refill the high-capacity system tanks after

emergencies or after extensive system testing. |