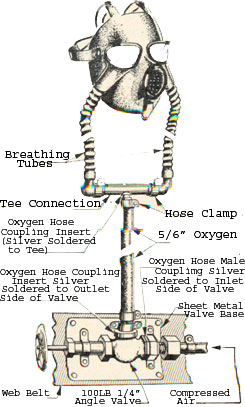

| There were many situations onboard ship that were

not considered an emergency but required breathing

protection (e.g., spray painting, entering a void or

tank, work on or around the CHT system). In a

non-casualty situation, the damage control assistant,

gas free engineer or his designated assistant had to

carefully evaluate all potential exposure to fumes,

gases or toxic hazards. The hose air-line mask was

developed in the 1940s for such situations. It could

also be used for diving in a tank or over the side under

controlled conditions (36-foot depth or less). It was

not used in firefighting. The first hose air-line mask

assemblies were developed in 1943. They were fabricated

using modified ND Mark III and ND Mark IV gas mask face

pieces. They had a dual air hose connected to an air

intake “T” attachment, supplied by a 5/16-inch inside

diameter by 50-foot rubber air hose that connected to a

compressed air bottle fitting. The compressor air bottle

contained 200 cubic feet of air. Fully charged, it

lasted the wearer 1 ½ to 2 ½ hours. A portable air hand

pump with an intervening air reservoir also was used. If

a hose was used to run out to fresh air, it could be no

longer than 25 feet with an inside diameter of 1 inch.

The assembly had a cotton harness, a safety belt and a

50-foot by 5/16-inch steel tending line with snap latch

hooks that attached to the “D” ring on the center of the

harness assembly. In 1951, development of the new hose

air-line mask was one of many measures undertaken for

personnel protection while Sailors were performing

various tasks onboard U.S. Navy ships. It was developed

to be used as a protective device worn by personnel

entering unsuitable atmospheres during routine work or

rescue, and later for shallow water (to 36 feet) diving

operations. By 1959, the U.S. Navy authorized the use of

a new hose air-line mask for shipboard equipment and

inclusion in the hull and repair locker allowance. This

new assembly had a redesigned, monocular face piece and

intervening pressure regulator. Onboard ships,

low-pressure air systems had air-line manifolds

installed for two or four hose air-line mask

connections; two stage regulators and air filters were

also installed, to reduce the pressure and remove

impurities from the air. One man could breathe

sufficiently through up to 250 feet of air hose. Long

runs of air hose had to be watched closely by tending

personnel to ensure that the line did not foul and that

the hose was kept off of hot decks. The new hose

air-line mask had a belt-mounted constant flow

respirator with a speaking diaphragm, full vision

plastic lens with adjustable head harness, breathing

tube, and a special body harness with a “D” ring on back

to attach the safety line. The constant flow regulator

created a slight positive pressure inside the mask. This

positive pressure ensured that no harmful air could leak

in and provided breathing air and eye protection in

spaces contaminated by any type of gas or vapor, and in

a space where there was a lack of oxygen. |